The Frigoglass advantage

Our innovative coolers enhance our customers’ branding impact at the point of sale and drive impulse consumption. In parallel to maximizing merchandising opportunities for our customers, we are committed to providing increasingly environmentally friendly product solutions which enable our customers to meet ambitious sustainability and carbon emission reduction targets.

Drive impulse demand in all trade channels

...creating exciting drinking experiences.

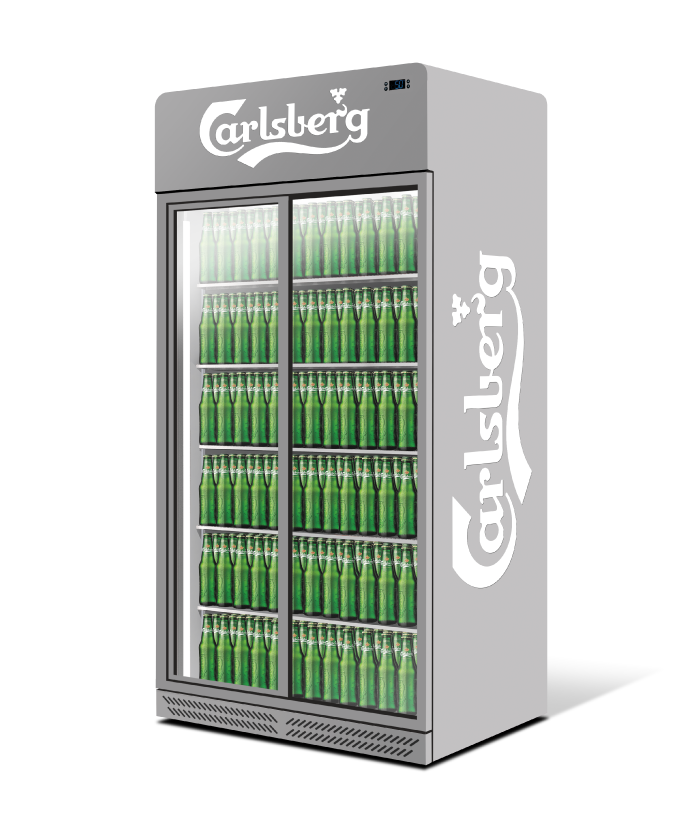

Branding, rebranding, upbranding

...by catering for all different customer placement needs.

Customization

We enhance our customer's brands differentiation at the point of sale.

Lighting

We put brands at the spotlight. Highly focused, cost-efficient LED illumination enables our customer's brands to stand out at the point of sale.

Interactive coolers

We provide complete value-adding solutions, allowing our customers to increase consumer engagement at the point of sale and enable advanced monitoring of cooler placement effectiveness.

Advanced merchandizing solutions

We implement innovative shelving solutions which boost sales performance.

Ideal temperature

We guarantee the perfect drinking experience for the end user keeping beverages at the right temperature, irrespective of the external conditions. Perfectly cold, always and anywhere.

Low noise

We offer best-in-class noise level of coolers using novel low-noise practices and innovations.

Product quality

Robust, all metal construction which allows for both outdoor and indoor placement, multiple relocations as well as for easy refurbishment, expanding the lifespan of the cooler. At the same time, the foul-free design of our products and the use of long life components minimize breakdown probability.

Robust, all metal construction which allows for both outdoor and indoor placement, multiple relocations as well as for easy refurbishment, expanding the lifespan of the cooler. At the same time, the foul-free design of our products and the use of long life components minimize breakdown probability.

Product quality

Robust, all metal construction which allows for both outdoor and indoor placement, multiple relocations as well as for easy refurbishment, expanding the lifespan of the cooler. At the same time, the foul-free design of our products and the use of long life components minimize breakdown probability.

Robust, all metal construction which allows for both outdoor and indoor placement, multiple relocations as well as for easy refurbishment, expanding the lifespan of the cooler. At the same time, the foul-free design of our products and the use of long life components minimize breakdown probability.

Easy servicing

Maintenance-free and easily serviceable coolers through the application of innovative construction such as slide-out cooling mechanisms, retractable electrical boxes and fast connectors.

Maintenance-free and easily serviceable coolers through the application of innovative construction such as slide-out cooling mechanisms, retractable electrical boxes and fast connectors.

Easy servicing

Maintenance-free and easily serviceable coolers through the application of innovative construction such as slide-out cooling mechanisms, retractable electrical boxes and fast connectors.

Maintenance-free and easily serviceable coolers through the application of innovative construction such as slide-out cooling mechanisms, retractable electrical boxes and fast connectors.

Integrated services

Providing customers with excellence in operations and best-in-class services, through a unique, innovative, integrated customer service program, materially supporting them in the management of their cold drink equipment fleet and allowing them to significantly reduce total cost of ownership as well as to dedicate even more time and resources on selling more beverages.

Providing customers with excellence in operations and best-in-class services, through a unique, innovative, integrated customer service program, materially supporting them in the management of their cold drink equipment fleet and allowing them to significantly reduce total cost of ownership as well as to dedicate even more time and resources on selling more beverages.

Integrated services

Providing customers with excellence in operations and best-in-class services, through a unique, innovative, integrated customer service program, materially supporting them in the management of their cold drink equipment fleet and allowing them to significantly reduce total cost of ownership as well as to dedicate even more time and resources on selling more beverages.

Providing customers with excellence in operations and best-in-class services, through a unique, innovative, integrated customer service program, materially supporting them in the management of their cold drink equipment fleet and allowing them to significantly reduce total cost of ownership as well as to dedicate even more time and resources on selling more beverages.

Connected coolers

Evocool, the new digital cooling device of Frigoglass, combines in a unique way the Frigoglass competence of energy optimization with the latest technology of remote connectivity including asset tracking capability. Our customers also benefit from real-time data transmission and advanced monitoring of cooler placement effectiveness.

Evocool, the new digital cooling device of Frigoglass, combines in a unique way the Frigoglass competence of energy optimization with the latest technology of remote connectivity including asset tracking capability. Our customers also benefit from real-time data transmission and advanced monitoring of cooler placement effectiveness.

Connected coolers

Evocool, the new digital cooling device of Frigoglass, combines in a unique way the Frigoglass competence of energy optimization with the latest technology of remote connectivity including asset tracking capability. Our customers also benefit from real-time data transmission and advanced monitoring of cooler placement effectiveness.

Evocool, the new digital cooling device of Frigoglass, combines in a unique way the Frigoglass competence of energy optimization with the latest technology of remote connectivity including asset tracking capability. Our customers also benefit from real-time data transmission and advanced monitoring of cooler placement effectiveness.

Green refrigerants

Pioneers in developing HFC-free solutions, both HC and CO2 since 2005, actively supporting and enabling our customers to meet ambitious sustainability targets.

Pioneers in developing HFC-free solutions, both HC and CO2 since 2005, actively supporting and enabling our customers to meet ambitious sustainability targets.

(large single door model)

(in thousand metric tons per 100K units)

Total recyclability

Our goal is to reduce materials use and recycle as much as possible. We aim to achieve this by developing products that use fewer materials as well as through advanced assembly techniques that facilitate disassembly and recyclability.

Our goal is to reduce materials use and recycle as much as possible. We aim to achieve this by developing products that use fewer materials as well as through advanced assembly techniques that facilitate disassembly and recyclability.

(Recyclable)

(Recyclable)

(Recyclable)

Electronics & LEDs,

Polyurethane,

Oil & Refrigerant

(Recyclable or

Properly Disposable)

Product life cycle assessment

“Cradle to grave” analysis of the impact our coolers have on the environment, through rigorous, interactive data gathering and gap analysis, examining our product’s lifecycle from the extraction of raw materials, through manufacture, transport, installation, use and disposal and identifying those specific stages that contribute the most to the cooler’s environmental footprint. Our detailed LCA findings feed into our product development process (both for existing and new products), aiming to make concentrated changes to further improve the efficiency of our complete product offering.

“Cradle to grave” analysis of the impact our coolers have on the environment, through rigorous, interactive data gathering and gap analysis, examining our product’s lifecycle from the extraction of raw materials, through manufacture, transport, installation, use and disposal and identifying those specific stages that contribute the most to the cooler’s environmental footprint. Our detailed LCA findings feed into our product development process (both for existing and new products), aiming to make concentrated changes to further improve the efficiency of our complete product offering.